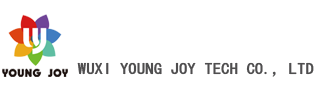

Alumina ceramic tube Customizable on demand

- 产品分类:Resistance tube

- 产品标签:ceramic

- 浏览次数:已有934位客户关注

- 联系方式:00 86 159 617 27024

Main forming methods of alumina ceramic tubes

For alumina ceramics, at the time of its forming, people were able to immediately add appropriate organic chemical preservatives in the slurry, so as to ensure that people's alumina ceramic slurry can have the actual effect of double electric layer on the surface of its particles. Moreover, it will be stable for itself, and it is not allowed It's easy to have any problems.

For alumina ceramics, in terms of its dry pressing method, it is only limited to the simplicity of appearance, and in terms of the thickness of people's inner cavity, it can only be 1 mm, or it can be used in commodities with diameter and length no more than 1:4. Only in terms of forming methods, they can be divided into transverse and single radial, and in terms of its press, they can be divided into mechanical equipment and hydraulic press.

Moreover, when your alumina ceramics are immediately dry pressing, people can not only develop fully automatic, but also fully automatic. Only for the press, its working pressure is only 150 MPa. For the production, it is necessary to ensure 16-60 pieces per minute. However, as for the working pressure of its hydraulic press in the stroke, it is relatively symmetrical, and it is not easy to be too large for the difference of its granular material.

For the forming method of alumina ceramic grouting, its appearance is relatively early. At that time, people must immediately apply gypsum mold, and the cost of its production and manufacturing is relatively low.

For alumina ceramics, when hollow grouting is carried out, and when the mold wall is immediately carrying out the suction of the material paddle, it has necessary regulations on its thickness, and it is necessary to pour out the excess material paddle. Then, it is said that in order to reduce the shrinkage of all the green bodies of alumina ceramics, it is necessary to carry out the reduction Less.

What is the difference between alumina ceramics and ordinary ceramics?

Alumina ceramic is a kind of ceramic material with alumina (Al2O3) as the main body, which is used in thick film integrated circuit. Alumina ceramics have good conductivity, mechanical strength and hi...

发表时间:2019-12-10

Changes of alumina ceramic structure at high temperature

Alumina ceramics is a kind of ceramics with alumina as the core, which is characterized by super high hardness, light weight, high heat conduction, high brittleness and wear resistance. Because cerami...

发表时间:2019-12-18

Toughening technology of alumina ceramic ring

Toughening technology of alumina ceramic ringMetal materials are easy to produce plastic deformation, because the metal bond is not directional. In ceramic materials, the bond between atoms is covalen...

发表时间:2019-12-14

Injection molding of alumina ceramic tube

Alumina ceramic tubes have excellent properties such as high mechanical strength, wear resistance, corrosion resistance, high temperature resistance, high thermal conductivity and resistivity. They ar...

发表时间:2019-12-10

Column navigation/Column menu

1What are the sintering and functions of alumina ceramics?

2019-12-19

2Changes of alumina ceramic structure at high temperature

2019-12-18

3Toughening technology of alumina ceramic ring

2019-12-14

4Injection molding of alumina ceramic tube

2019-12-10

5What is the difference between alumina ceramics and ordinary ceramics?

2019-12-10

6What can alumina ceramics be used for?

2019-12-09

7What are the preparation methods of alumina ceramics?

2019-12-09

8Introduction of sintering process of alumina ceramics

2019-12-09