Changes of alumina ceramic structure at high temperature

Alumina ceramics is a kind of ceramics with alumina as the core, which is characterized by super high hardness, light weight, high heat conduction, high brittleness and wear resistance. Because ceramics have both hardness and brittleness, they are difficult to machine. The common methods in the industry are grinding, cutting, laser heating, high-pressure abrasive water jet and ultrasonic machining. What is the change of alumina ceramic structure under high temperature?

1、 Creep

The structural parts of alumina ceramics will be affected by external forces at high temperature. With the increase of time, the plasticity will change continuously and slowly. This phenomenon can be called creep. When the structural parts of alumina ceramics creep, there is a great relationship between stress and temperature. In addition, when the stress increases or the temperature increases, the creep rate will also increase.

2、 Graphitization and spheroidization

Because graphite is relatively low in strength and mainly presents in flakes, it will lead to a lot of reduction in strength of materials, and the brittleness will also increase, so we call it graphitization. At the same time, in the case of high temperature, there will be a lot of cementite in the structural parts of alumina ceramics. Because of the large energy obtained, there will be aggregation or migration, which will change into cementite with coarse grains, and it will be directly mixed in ferrite. The main thing is that the cementite will gradually change from flake to sphere, so we call it spheroidization.

3、 Thermal fatigue properties

If the alumina ceramic structure is in the condition of alternating hot and cold for a long time, the error of the material itself will change due to the effect of thermal stress, and will gradually appear small cracks, which will eventually lead to serious cracking. Therefore, it is necessary to consider the thermal fatigue of alumina ceramic structure when the temperature fluctuates greatly.

previous page:period…

next page:What is the difference between alumina ceramics and ordinary ceramics?

What are the sintering and functions of alumina ceramics?

The strength of alumina ceramics is only a millionth different from that of diamond. However, if alumina ceramics and wear-resistant steel, or stainless steel plates are used to develop wear resistanc...

Time of publication:2019-12-19

Changes of alumina ceramic structure at high temperature

Alumina ceramics is a kind of ceramics with alumina as the core, which is characterized by super high hardness, light weight, high heat conduction, high brittleness and wear resistance. Because cerami...

Time of publication:2019-12-18

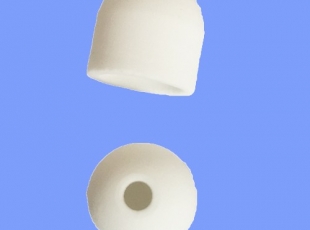

Toughening technology of alumina ceramic ring

Toughening technology of alumina ceramic ringMetal materials are easy to produce plastic deformation, because the metal bond is not directional. In ceramic materials, the bond between atoms is covalen...

Time of publication:2019-12-14

Injection molding of alumina ceramic tube

Alumina ceramic tubes have excellent properties such as high mechanical strength, wear resistance, corrosion resistance, high temperature resistance, high thermal conductivity and resistivity. They ar...

Time of publication:2019-12-10

What is the difference between alumina ceramics and ordinary ceramics?

Alumina ceramic is a kind of ceramic material with alumina (Al2O3) as the main body, which is used in thick film integrated circuit. Alumina ceramics have good conductivity, mechanical strength and hi...

Time of publication:2019-12-10

What can alumina ceramics be used for?

Application of alumina ceramics 1. Mechanical The bending strength of Al2O3 sintered products can reach 250Mpa, and that of hot pressed products can reach 500MPa...

Time of publication:2019-12-09

What are the preparation methods of alumina ceramics?

Preparation of alumina ceramics 1. Preparation of powderAluminum oxide powder is prepared into powder materials according to different product requirements and different molding pr...

Time of publication:2019-12-09

Introduction of sintering process of alumina ceramics

Introduction of sintering process of alumina ceramics 1. Atmospheric sinteringSintering at atmospheric pressure means that materials are sintered under atmospheric pres...

Time of publication:2019-12-09

Column navigation/Column menu

1What are the sintering and functions of alumina ceramics?

2019-12-19

2Changes of alumina ceramic structure at high temperature

2019-12-18

3Toughening technology of alumina ceramic ring

2019-12-14

4Injection molding of alumina ceramic tube

2019-12-10

5What is the difference between alumina ceramics and ordinary ceramics?

2019-12-10

6What can alumina ceramics be used for?

2019-12-09