What are the sintering and functions of alumina ceramics?

The strength of alumina ceramics is only a millionth different from that of diamond. However, if alumina ceramics and wear-resistant steel, or stainless steel plates are used to develop wear resistance, their overall wear resistance should be higher than many, which is why alumina ceramics have such a key influence in the manufacturing industry and ensure that they are obtained in different manufacturing industries Good development trend.

First of all, alumina ceramic is very light in net weight, and it keeps pace with steel on the basis of relative density, especially because alumina ceramic has such high relative density. If it is used as parts of machinery and equipment, it is reasonable to like which machinery and equipment to reduce the load, and ensure all normal operation of machinery and equipment, and it is not easy to align the machine Equipment causes all hazards.

Secondly, alumina ceramics have very high wear resistance, which is many times higher than manganese steel in general. If alumina ceramics or manganese steel are used under the same conditions, the advantages of alumina ceramics in application are very prominent, at least five times more than manganese steel, so that it has a longer term and is not easy to be damaged.

On the market, this new technical way of alumina ceramics appears. It is necessary to immediately carry out crystal plating on the surface of alumina ceramics. The more commonly used methods are radiation crystal plating, vacuum coating or phase evaporation crystal plating of electronic devices. These different technical methods can reasonably strengthen and improve the processing technology of alumina ceramics.

In fact, that is to say, the surface of alumina ceramics is coated with silicon chemicals. Usually, it must be carried out at a high temperature between 1500 ℃ - 1580 ℃. The key factor of selecting such high temperature is to ensure the explosion-proof glass level of alumina ceramics stronger, and to moderately and reasonably improve the compressive strength of alumina ceramics.

In fact, alumina ceramic is a kind of product that uses iron oxide as the key raw material to produce or manufacture this kind of porcelain. The key is to apply it to thick film integrated circuit chip. Moreover, alumina ceramic is very good in conductivity, heat resistance and pressure resistance of mechanical equipment. However, when alumina ceramic is applied, special attention must be paid to the area It is ultrasonic cleaning, and alumina ceramics are widely used in the field of application, because alumina ceramics are very excellent in characteristics, so in many different manufacturing industries, its application is very common, which can consider the usual application requirements, and some of its more required characteristics, alumina ceramics in the manufacturing industry application is very Obvious.

In the production and manufacturing of alumina ceramics, the key is to calcine the raw materials through high-density methods. The key purpose of calcination is to clean the gap between the ceramic body and the particles, and to exhaust a small amount of steam and magazines and periodicals, so as to ensure the long-term development and integration of the particles, and to produce chemical free materials Production and processing methods of materials.

Although the continuous pressing calcination method can reasonably improve the production of alumina ceramics, due to the application of production equipment, and its related manufacturing costs are relatively high, and the radial direction is not very symmetrical in heat, so the length of alumina ceramics crafts will be subject to the hazards due to the above problems, because of alumina ceramics Porcelain has excellent precision in structure. Raw materials have the same characteristics as cold pressing calcination, which can improve the characteristics by 25% to 50%, much higher than ordinary alumina ceramic products. At present, alumina ceramic products are widely used in many unique parts, such as Fresnel lens and ceramic rolling bearing.

previous page:period…

What are the sintering and functions of alumina ceramics?

The strength of alumina ceramics is only a millionth different from that of diamond. However, if alumina ceramics and wear-resistant steel, or stainless steel plates are used to develop wear resistanc...

Time of publication:2019-12-19

Changes of alumina ceramic structure at high temperature

Alumina ceramics is a kind of ceramics with alumina as the core, which is characterized by super high hardness, light weight, high heat conduction, high brittleness and wear resistance. Because cerami...

Time of publication:2019-12-18

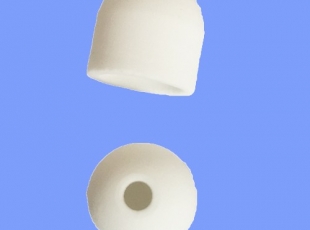

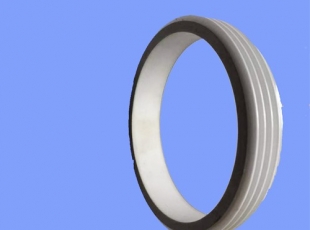

Toughening technology of alumina ceramic ring

Toughening technology of alumina ceramic ringMetal materials are easy to produce plastic deformation, because the metal bond is not directional. In ceramic materials, the bond between atoms is covalen...

Time of publication:2019-12-14

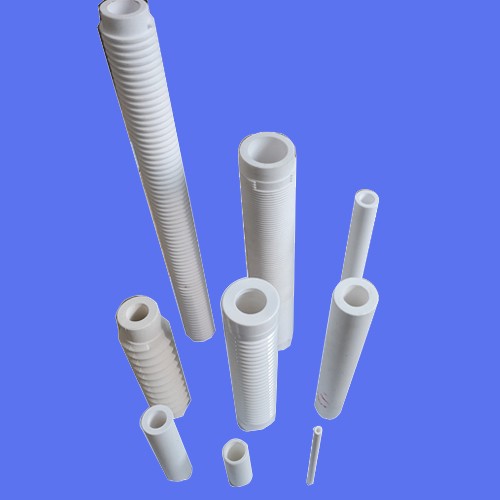

Injection molding of alumina ceramic tube

Alumina ceramic tubes have excellent properties such as high mechanical strength, wear resistance, corrosion resistance, high temperature resistance, high thermal conductivity and resistivity. They ar...

Time of publication:2019-12-10

What is the difference between alumina ceramics and ordinary ceramics?

Alumina ceramic is a kind of ceramic material with alumina (Al2O3) as the main body, which is used in thick film integrated circuit. Alumina ceramics have good conductivity, mechanical strength and hi...

Time of publication:2019-12-10

What can alumina ceramics be used for?

Application of alumina ceramics 1. Mechanical The bending strength of Al2O3 sintered products can reach 250Mpa, and that of hot pressed products can reach 500MPa...

Time of publication:2019-12-09

What are the preparation methods of alumina ceramics?

Preparation of alumina ceramics 1. Preparation of powderAluminum oxide powder is prepared into powder materials according to different product requirements and different molding pr...

Time of publication:2019-12-09

Introduction of sintering process of alumina ceramics

Introduction of sintering process of alumina ceramics 1. Atmospheric sinteringSintering at atmospheric pressure means that materials are sintered under atmospheric pres...

Time of publication:2019-12-09

Column navigation/Column menu

1What are the sintering and functions of alumina ceramics?

2019-12-19

2Changes of alumina ceramic structure at high temperature

2019-12-18

3Toughening technology of alumina ceramic ring

2019-12-14

4Injection molding of alumina ceramic tube

2019-12-10

5What is the difference between alumina ceramics and ordinary ceramics?

2019-12-10

6What can alumina ceramics be used for?

2019-12-09