Introduction of sintering process of alumina ceramics

Introduction of sintering process of alumina ceramics

1. Atmospheric sintering

Sintering at atmospheric pressure means that materials are sintered under atmospheric pressure without pressure, which is a common sintering method. It includes atmospheric sintering in air condition and atmospheric sintering in a special gas atmosphere. This method has higher sintering temperature, higher requirements for furnace, and greater waste of energy.

Because of the high melting point of Al2O3, it is often necessary to add sintering aids to the preparation of Al2O3 ceramics. This method can generally promote the sintering of Al2O3 ceramics. The liquid phase sintering of Al2O3 ceramics can generate liquid phase through chemical reaction, promote diffusion and viscous flow, so as to achieve the process of particle rearrangement and mass transfer, reduce the sintering temperature of Al2O3 ceramics, and accelerate the effective sintering.

Because there is no external driving force in the sintering process, it is very difficult to eliminate all the pores in the ceramic to reach the theoretical density. The special sintering process refers to the addition of sintering driving force in the sintering process of alumina ceramics to promote the densification of ceramics. At present, the common special sintering processes are hot pressing sintering, hot isostatic pressing sintering, microwave heating sintering, microwave plasma sintering, discharge plasma sintering and so on.

2. Hot press sintering

Hot pressing sintering is to apply unidirectional pressure on the sample at high temperature to promote the ceramic to achieve full densification. Compared with conventional sintering, sintering at 15MPa reduced the sintering temperature by 200 ℃ and increased the density by 2%, and this trend increased with the increase of pressure. For pure alumina ceramics, conventional sintering needs a temperature above 1800 ℃, while hot pressing sintering of 20MPa only needs 1500 ℃.

The pressure provided by hot pressing sintering promotes the flow of atoms in the particles, while the pressure and surface energy act as driving forces to enhance the diffusion. Because the hot pressing sintering can be sintered at a lower temperature, the grain growth is controlled, and the samples are dense and uniform, with small grains and high strength. However, it is not suitable to produce products with high thickness, complex shape, small production scale and high cost.

3. Hip sintering

Hot isostatic pressing (hip) sintering is a kind of sintering process that applies pressure to all directions of the ceramic body at the same time, reduces the sintering temperature of the ceramic body, and at the same time, the ceramic structure obtained by sintering is uniform and the performance is good. Although hip sintering can successfully reduce the sintering temperature of ceramics, and can obtain complex shaped objects, but hip sintering needs to pack or pre sinter the body in advance, and the pressure conditions will be more stringent.

4. Ultrahigh pressure sintering

Ultrahigh pressure sintering means sintering under high pressure. Due to the large pressure, the diffusion of atoms is controlled, and the potential barrier of nucleation is relatively small, so high-density (> 98%) high-purity alumina ceramics can be produced at low temperature. In the process of ultra-high pressure sintering, the existence of pressure increases the vacancy and diffusion rate of atoms in the particles, and the pressure and surface energy together act as the driving force of sintering to enhance the diffusion. The ultra-high pressure sintering usually only needs to be carried out at a relatively low temperature, which controls the abnormal growth of grains, so as to obtain high-purity alumina ceramics with high density, fine grain size and uniform distribution.

5. Microwave sintering

Microwave heating sintering uses the interaction between microwave and ceramics, because the dielectric effect makes the internal and surface of ceramics sintered at the same time. Microwave sintering is different from other sintering methods, its hot gas flow is from inside to outside, which is conducive to the gas diffusion inside the billet; at the same time, microwave makes the activity of grains improve, and it is easier to migrate, so as to promote densification.

Compared with other sintering methods, microwave sintering can increase the temperature rapidly, and the temperature field is uniform, the thermal stress is small, and there is no pollution. The sintering temperature of microwave sintering is 100 ℃ to 150 ℃ lower than that of conventional sintering, and the sintering time is one order of magnitude less than that of conventional sintering. Under the same conditions, the density of microwave sintering is obviously higher than that of conventional sintering. Microwave sintering can be used to sinter complex objects, and after sintering, the internal grains of ceramics are small, the homogeneity is good, and the fracture toughness is good.

6. Microwave plasma sintering

Compared with conventional sintering, microwave plasma sintering can reduce the sintering temperature by 200 ℃ under the same conditions, and the sintering speed is fast, the grain size is small, and the mechanical strength is high. One of the reasons that microwave plasma sintering promotes densification is that the rapid temperature rise reduces the grain growth caused by surface diffusion, provides a strong driving force and a short distance for volume diffusion and grain boundary diffusion, so as to reduce the sintering temperature of alumina ceramics and refine the grain.

7. Spark plasma sintering

Spark plasma sintering is a relatively new sintering method developed in recent years. It uses the instantaneous high temperature field generated by pulse energy and pulse pressure to realize the spontaneous heating of the internal grains of ceramics so as to activate the grains. Because of this sintering method's fast heating, cooling and short holding time, it controls the growth of grains, shortens the preparation period of ceramics and saves energy. In fact, spark plasma sintering is a new hot pressing sintering method. The ceramic samples obtained are of uniform grain, high density and good mechanical properties. It is a very valuable and promising sintering method.

In the process of preparing high-purity alumina ceramics by spark plasma sintering, the heating rate has a great influence on the densification of samples in different stages. In the initial stage of sintering, faster heating rate can increase the density of sinter, but in the later stage of sintering, faster heating rate can reduce the density of sinter.

8. Two step sintering

The two-step sintering method is to heat the sample to a specific temperature (T1) to eliminate the subcritical pores in the billet, and then reduce it to a lower temperature (T2) to make the billet compact. In the low-temperature sintering stage of the two-step sintering method, because the activation energy required by the grain boundary diffusion is higher than the grain boundary migration, the grain boundary diffusion is the main stage. Therefore, in the second stage of the two-step sintering process, the green body is continuously densified, but the grain will not grow too fast. In the low temperature sintering stage of the two-step sintering method, the prerequisite for the complete densification of the green body is that during the shrinkage of the green body, the pores in the green body gradually become closed pores.

9. Microwave two-step sintering

The two-step sintering can be carried out on the traditional sintering furnace with low equipment cost and strong application value. However, two-step sintering is a relatively slow sintering process because it needs to be kept at the second temperature point for a long time. Microwave heating usually has the advantages of whole heating and fast heating. Few researches combine microwave heating with two-step heating. However, microwave heating can reduce the sintering temperature and shorten the sintering time, which will be conducive to further refinement of grains and effectively shorten the production cycle of two-step process.

10. High vacuum sintering

High vacuum sintering is a kind of sintering technology for ceramic body in high vacuum state. Because of the advantages of vacuum sintering, such as reducing the heating rate, controlling the abnormal growth of grains and reducing the irregular porosity, many scholars pay attention to the preparation of low porosity and small-size grain ceramics.

High vacuum sintering can not only enhance some properties of high-purity alumina ceramics, but also reduce impurities at the grain boundary and pores in the sinter. In the process of preparing high-purity alumina ceramics by vacuum sintering, oxygen ions in the lattice of alumina are easy to be lost, forming a large number of oxygen ion vacancies, and the relative increase of aluminum ion concentration, which results in the acceleration of aluminum ion diffusion process, which is conducive to the sintering process.

previous page:What are the preparation methods of alumina ceramics?

next page:period…

What are the sintering and functions of alumina ceramics?

The strength of alumina ceramics is only a millionth different from that of diamond. However, if alumina ceramics and wear-resistant steel, or stainless steel plates are used to develop wear resistanc...

Time of publication:2019-12-19

Changes of alumina ceramic structure at high temperature

Alumina ceramics is a kind of ceramics with alumina as the core, which is characterized by super high hardness, light weight, high heat conduction, high brittleness and wear resistance. Because cerami...

Time of publication:2019-12-18

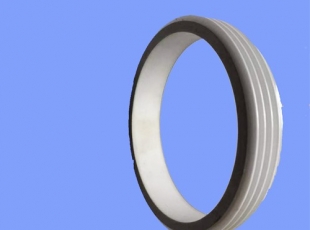

Toughening technology of alumina ceramic ring

Toughening technology of alumina ceramic ringMetal materials are easy to produce plastic deformation, because the metal bond is not directional. In ceramic materials, the bond between atoms is covalen...

Time of publication:2019-12-14

Injection molding of alumina ceramic tube

Alumina ceramic tubes have excellent properties such as high mechanical strength, wear resistance, corrosion resistance, high temperature resistance, high thermal conductivity and resistivity. They ar...

Time of publication:2019-12-10

What is the difference between alumina ceramics and ordinary ceramics?

Alumina ceramic is a kind of ceramic material with alumina (Al2O3) as the main body, which is used in thick film integrated circuit. Alumina ceramics have good conductivity, mechanical strength and hi...

Time of publication:2019-12-10

What can alumina ceramics be used for?

Application of alumina ceramics 1. Mechanical The bending strength of Al2O3 sintered products can reach 250Mpa, and that of hot pressed products can reach 500MPa...

Time of publication:2019-12-09

What are the preparation methods of alumina ceramics?

Preparation of alumina ceramics 1. Preparation of powderAluminum oxide powder is prepared into powder materials according to different product requirements and different molding pr...

Time of publication:2019-12-09

Introduction of sintering process of alumina ceramics

Introduction of sintering process of alumina ceramics 1. Atmospheric sinteringSintering at atmospheric pressure means that materials are sintered under atmospheric pres...

Time of publication:2019-12-09

Column navigation/Column menu

1What are the sintering and functions of alumina ceramics?

2019-12-19

2Changes of alumina ceramic structure at high temperature

2019-12-18

3Toughening technology of alumina ceramic ring

2019-12-14

4Injection molding of alumina ceramic tube

2019-12-10

5What is the difference between alumina ceramics and ordinary ceramics?

2019-12-10

6What can alumina ceramics be used for?

2019-12-09