What can alumina ceramics be used for?

Application of alumina ceramics

1. Mechanical

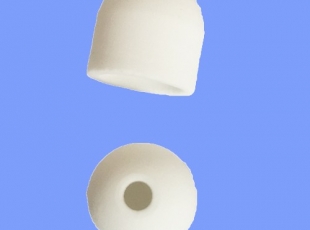

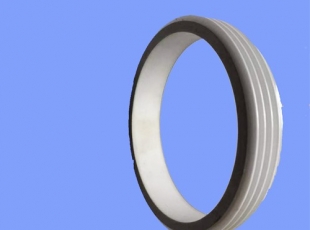

The bending strength of Al2O3 sintered products can reach 250Mpa, and that of hot pressed products can reach 500MPa. The Mohs hardness of Al2O3 ceramics is up to 9. In addition, Al2O3 ceramics has excellent wear resistance, so it is widely used in manufacturing tools, ball valves, grinding wheels, ceramic nails, bearings, etc., among which Al2O3 ceramics tools and industrial valves are widely used.

1.1 pure Al2O3 Ceramic Tool

Pure Al2O3 ceramic tool is a kind of high-purity Al2O3 ceramic with only a small amount of oxide, and the purity of Al2O3 is more than 99%. In pure Al2O3 ceramics, ZrO2 can be added as sintering assistant to improve its fracture toughness. At present, the grain size of Al2O3 ceramics prepared by ordinary sintering is in the micron level, and fine-grained Al2O3 ceramics can obtain higher strength, fracture toughness and better high temperature performance, which is an ideal material for preparing pure Al2O3 ceramic tools.

1.2 composite Al2O3 Ceramic Tool

In composite ceramics, there are several composite directions: Al2O3 carbide ceramic tool, Al2O3 carbide cermet tool, Al2O3 nitride or boride ceramic tool, etc. Al2O3 carbide ceramic cutting tool is to add some carbides to Al2O3 to improve its strength, wear resistance, impact resistance and high temperature performance.

Compared with pure Al2O3 ceramics, the bending strength of Al2O3 carbide composite ceramics is better than that of pure Al2O3 ceramics at room or high temperature. This composite tool is suitable for high speed rough and finish machining of wear-resistant cast iron, hardened steel and high-strength steel and other difficult to machine materials. Al2O3 carbide cermet tool is a kind of tool which can be used to process quenched steel, alloy steel, manganese steel, chilled cast iron, nickel base and cobalt base alloy as well as non-metallic materials.

It is a better tool for finishing chilled cast iron roll at present, and it can be used in cutting occasions with cutting fluid and discontinuous cutting.

1.3 toughened Al2O3 Ceramic Tool

Toughened Al2O3 ceramic tool is to add toughening or reinforcing materials to Al2O3 matrix. At present, the commonly used toughening methods are: ZrO2 phase transformation toughening, whisker toughening, second phase particle dispersion toughening and so on. ZrO2 transformation toughening is an effective way of toughening. When ZrO2 transforms at about 1150 ℃, the volume changes, and many cracks are induced in the matrix, so as to absorb most of the energy at the top of the main crack and achieve the purpose of toughening. The fracture toughness of Al2O3 ceramic tool made of Al2O3 toughened by ZrO2 phase transformation can be improved effectively.

2. Electronics and power

In the field of electronics and electric power, there are various Al2O3 ceramic soleplates, substrates, ceramic films, transparent ceramics and various Al2O3 ceramic electrical insulating ceramics, electronic materials, magnetic materials, etc., among which Al2O3 transparent ceramics and substrates are widely used.

2.1 Al2O3 transparent ceramics

According to its application, transparent ceramics can be divided into two categories: light transmission, wave transmission application and special light function application.

In the application of light transmission and wave transmission, new energy-saving lamps made of transparent Al2O3 ceramics are used, such as metal halide lamps, high-strength transparent armor materials, infrared wave transmission materials, etc., which are important materials in civil and national defense equipment. Mgal2o3 transparent ceramics belong to this kind of materials. It not only has the characteristics of ceramics, but also has the optical properties of sapphire crystal and quartz glass. It can be used in transparent armor, lighting and so on.

In the application of special optical functional characteristics, there are thin-film luminescent materials, high-power all solid-state lasers, transparent scintillation ceramics and so on. Al2O3, one of the thin-film luminescent materials, has been proved to be a promising thin-film luminescent material because of its high transparency, good thermal stability and relatively high luminosity.

2.2 Al2O3 ceramic substrate

Al2O3 ceramic substrate is widely used in multilayer wiring ceramic substrate, electronic packaging and high-density packaging substrate because of its high mechanical strength, good insulation and high light resistance. In the preparation of Al2O3 ceramic substrate, the common forming methods are dry pressing, casting, etc., and casting is widely used at present. Flow casting can be divided into non water system and water system: the non water system flow casting process is simple, but it will cause environmental pollution and high cost; the water system flow casting process is more environmentally friendly and low cost, but the process is difficult.

At present, most of the industrial applications use non water flow casting to form Al2O3 ceramic substrate. The Al2O3 ceramic substrate with smooth surface, flat surface and high density can be prepared by non water flow casting, but in the preparation process, the sintering temperature of the substrate is high and the energy consumption is large. Therefore, some additives can be added to the Al2O3 ceramic substrate to reduce the sintering temperature. For example, adding Fe Cr Mn system black pigment to prepare the black Al2O3 ceramic substrate can effectively reduce the sintering temperature and energy consumption of Al2O3 ceramic substrate under other conditions with the same performance.

3. Chemical industry

In the field of chemical application, Al2O3 ceramic also has a wide range of applications, such as Al2O3 ceramic chemical filler ball, inorganic microfiltration membrane, corrosion-resistant coating, etc., among which Al2O3 ceramic membrane and coating are widely studied and applied.

Al2O3 ceramic membrane has been widely used in water purification, desalination, gas separation, catalytic reaction and so on. Therefore, ceramic inorganic membrane has been paid more and more attention by the scientific and industrial circles. There are many preparation methods of Al2O3 ceramic film, such as sol-gel method, solid particle sintering method, chemical vapor deposition method, anodizing method, etc.

4. Medical

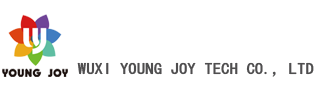

In medicine, Al2O3 is more used to make artificial bone, artificial joint, artificial teeth and so on. Al2O3 ceramics have excellent biocompatibility, biological inertia, physical and chemical stability, high hardness, high wear resistance, and are ideal materials for the preparation of artificial bone and artificial joint. However, it has the same disadvantages as other ceramic materials, such as high brittleness, low fracture toughness, high machining technology difficulty, complex technology, etc., so it needs further research and application.

5. Other aspects

Al2O3 ceramic is one of the materials which are widely used and researched in the new materials. In addition to the above applications, it is also widely used in other high-tech fields, such as aerospace, high-temperature industrial furnace, composite reinforcement and other fields.

previous page:Injection molding of alumina ceramic tube

next page:period…

What are the sintering and functions of alumina ceramics?

The strength of alumina ceramics is only a millionth different from that of diamond. However, if alumina ceramics and wear-resistant steel, or stainless steel plates are used to develop wear resistanc...

Time of publication:2019-12-19

Changes of alumina ceramic structure at high temperature

Alumina ceramics is a kind of ceramics with alumina as the core, which is characterized by super high hardness, light weight, high heat conduction, high brittleness and wear resistance. Because cerami...

Time of publication:2019-12-18

Toughening technology of alumina ceramic ring

Toughening technology of alumina ceramic ringMetal materials are easy to produce plastic deformation, because the metal bond is not directional. In ceramic materials, the bond between atoms is covalen...

Time of publication:2019-12-14

Injection molding of alumina ceramic tube

Alumina ceramic tubes have excellent properties such as high mechanical strength, wear resistance, corrosion resistance, high temperature resistance, high thermal conductivity and resistivity. They ar...

Time of publication:2019-12-10

What is the difference between alumina ceramics and ordinary ceramics?

Alumina ceramic is a kind of ceramic material with alumina (Al2O3) as the main body, which is used in thick film integrated circuit. Alumina ceramics have good conductivity, mechanical strength and hi...

Time of publication:2019-12-10

What can alumina ceramics be used for?

Application of alumina ceramics 1. Mechanical The bending strength of Al2O3 sintered products can reach 250Mpa, and that of hot pressed products can reach 500MPa...

Time of publication:2019-12-09

What are the preparation methods of alumina ceramics?

Preparation of alumina ceramics 1. Preparation of powderAluminum oxide powder is prepared into powder materials according to different product requirements and different molding pr...

Time of publication:2019-12-09

Introduction of sintering process of alumina ceramics

Introduction of sintering process of alumina ceramics 1. Atmospheric sinteringSintering at atmospheric pressure means that materials are sintered under atmospheric pres...

Time of publication:2019-12-09

Column navigation/Column menu

1What are the sintering and functions of alumina ceramics?

2019-12-19

2Changes of alumina ceramic structure at high temperature

2019-12-18

3Toughening technology of alumina ceramic ring

2019-12-14

4Injection molding of alumina ceramic tube

2019-12-10

5What is the difference between alumina ceramics and ordinary ceramics?

2019-12-10

6What can alumina ceramics be used for?

2019-12-09