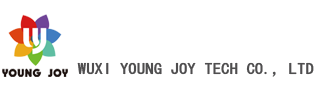

Alumina ceramic tube Service in place

- 产品分类:Resistance tube

- 产品标签:ceramic

- 浏览次数:已有881位客户关注

- 联系方式:00 86 159 617 27024

Hot pressing technology of alumina ceramic tube

At this stage, the vast majority of alumina ceramic tubes are made by the overall forging process, which has many advantages compared with the traditional production process. In order to ensure the quality of alumina ceramic tubes, and to add the pressing process to the overall forging process, what are the countermeasures to solve this problem?

Generally speaking, the alumina ceramic pipe is made by pouring the formed ceramic pipe concrete into the seamless steel pipe with the masterbatch filled with treasures. Because the iron oxide content of the ceramic pipe lined by the alumina ceramic pipe is higher than 96%, plus the 150t dry compression molding, the alumina ceramic pipe obtained can not have a smooth inner cavity, good airtightness, but also has good wear resistance and corrosion resistance 。

In the past, the lean production method of alumina ceramic pipes was to sinter ceramic powder into ceramic pipes according to grinding tools, and then integrate it with seamless steel pipes. At the same time, the products were very easy to crack due to the rapid temperature reduction in the furnace during the whole calcination process, and the processing technology was very complex, so as to improve the ductility of alumina ceramic pipes. Considering the specifications and corrosion resistance in application, alumina ceramic pipes At that time, the pressing process was necessary for the overall forging and firing of porcelain tubes. You also need to carry out pre-stressed tensioning before, in order to avoid the defects such as core lamination and seam separation caused by the deviation of alumina ceramic tubes when they are installed into the panel splicing machine. Before the pressing after the blank assembly, you need to carry out pre-stressed tensioning under the indoor temperature, so that they can be bonded into one overall raw material. Then the hot plywood processing technology is selected to carry out the pressing of alumina ceramic tubes. The pressing temperature is 160 ℃ up and down, and the working pressure of the enterprise is 2.3-5.0mpa. The pressing time is calculated according to the thickness of the finished alumina ceramic tubes. Don't forget to solve the problem of lowering the blood pressure in several stages as the later production process of pressing. The purpose is to avoid the bulge problem of alumina ceramic tubes. After the above discussion, we have The three-layer alumina ceramic tube can be pressed to solve the problem, and the bottom limit should be considered.

What is the difference between alumina ceramics and ordinary ceramics?

Alumina ceramic is a kind of ceramic material with alumina (Al2O3) as the main body, which is used in thick film integrated circuit. Alumina ceramics have good conductivity, mechanical strength and hi...

发表时间:2019-12-10

Changes of alumina ceramic structure at high temperature

Alumina ceramics is a kind of ceramics with alumina as the core, which is characterized by super high hardness, light weight, high heat conduction, high brittleness and wear resistance. Because cerami...

发表时间:2019-12-18

Toughening technology of alumina ceramic ring

Toughening technology of alumina ceramic ringMetal materials are easy to produce plastic deformation, because the metal bond is not directional. In ceramic materials, the bond between atoms is covalen...

发表时间:2019-12-14

Injection molding of alumina ceramic tube

Alumina ceramic tubes have excellent properties such as high mechanical strength, wear resistance, corrosion resistance, high temperature resistance, high thermal conductivity and resistivity. They ar...

发表时间:2019-12-10

Column navigation/Column menu

1What are the sintering and functions of alumina ceramics?

2019-12-19

2Changes of alumina ceramic structure at high temperature

2019-12-18

3Toughening technology of alumina ceramic ring

2019-12-14

4Injection molding of alumina ceramic tube

2019-12-10

5What is the difference between alumina ceramics and ordinary ceramics?

2019-12-10

6What can alumina ceramics be used for?

2019-12-09

7What are the preparation methods of alumina ceramics?

2019-12-09

8Introduction of sintering process of alumina ceramics

2019-12-09