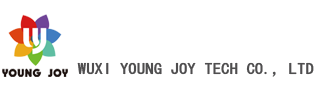

Alumina ceramic Filter cup

- 产品分类:Filter cup

- 产品标签:ceramic

- 浏览次数:已有1520位客户关注

- 联系方式:00 86 159 617 27024

Sintering technology of alumina ceramics

The technical method of densifying granular ceramic body and forming solid materials is called sintering. Sintering is the method of removing the void between the particles in the body, removing a small amount of gas and impurities and organic matters, so that the particles grow and combine with each other to form new substances.

The electric furnace is widely used in the heating device for firing. In addition to atmospheric pressure sintering, there are also hot pressing sintering and hot isostatic pressing sintering. Although the continuous hot pressing sintering can increase the output, the cost of equipment and mould is too high. In addition, due to the axial heating, the length of products is limited. The high temperature and high pressure gas is used as the pressure transfer medium in the hot isostatic pressure sintering, which has the advantage of uniform heating in all directions, and is very suitable for the sintering of complex shaped products. Due to the uniform structure, the properties of the material are 30-50% higher than that of cold pressed sintering. It is 10-15% higher than that of conventional hot pressing sintering. Therefore, some special parts for high value-added alumina ceramic products, such as ceramic bearings, reflectors, nuclear fuel and barrel, are fired by hot isostatic pressing.

In addition, microwave sintering, arc plasma sintering and self propagating sintering are also under development.

Finishing and packaging process

Some alumina ceramics need to be finished after sintering. For example, the products that can be used as artificial bone require high surface finish, such as mirror surface, to increase the lubricity. Due to the high hardness of alumina ceramic material, it is necessary to finish it with harder grinding and polishing brick material. Such as SiC, B4C or diamond. It is usually used to grind from coarse to fine abrasive and then polish the surface. Generally, Al2O3 powder or diamond paste of < 1 μ m μ M can be used for grinding and polishing. In addition, the laser processing and ultrasonic processing grinding and polishing methods can also be used.

Strengthening process of alumina ceramics

In order to enhance the mechanical strength of alumina ceramics, a new strengthening process of alumina ceramics was developed abroad. The process is novel and simple, and the technical means adopted is to use electronic ray vacuum coating, sputtering vacuum coating or chemical vapor deposition on the surface of alumina ceramics, to coat a layer of silicon compound film, and heat treatment at 1200 ℃ ~ 1580 ℃ to toughen alumina ceramics.

The mechanical strength of the strengthened alumina ceramics can be greatly increased on the original basis, and the alumina ceramics with ultra-high strength can be obtained.

What is the difference between alumina ceramics and ordinary ceramics?

Alumina ceramic is a kind of ceramic material with alumina (Al2O3) as the main body, which is used in thick film integrated circuit. Alumina ceramics have good conductivity, mechanical strength and hi...

发表时间:2019-12-10

Changes of alumina ceramic structure at high temperature

Alumina ceramics is a kind of ceramics with alumina as the core, which is characterized by super high hardness, light weight, high heat conduction, high brittleness and wear resistance. Because cerami...

发表时间:2019-12-18

Toughening technology of alumina ceramic ring

Toughening technology of alumina ceramic ringMetal materials are easy to produce plastic deformation, because the metal bond is not directional. In ceramic materials, the bond between atoms is covalen...

发表时间:2019-12-14

Injection molding of alumina ceramic tube

Alumina ceramic tubes have excellent properties such as high mechanical strength, wear resistance, corrosion resistance, high temperature resistance, high thermal conductivity and resistivity. They ar...

发表时间:2019-12-10

Column navigation/Column menu

1What are the sintering and functions of alumina ceramics?

2019-12-19

2Changes of alumina ceramic structure at high temperature

2019-12-18

3Toughening technology of alumina ceramic ring

2019-12-14

4Injection molding of alumina ceramic tube

2019-12-10

5What is the difference between alumina ceramics and ordinary ceramics?

2019-12-10

6What can alumina ceramics be used for?

2019-12-09

7What are the preparation methods of alumina ceramics?

2019-12-09

8Introduction of sintering process of alumina ceramics

2019-12-09